10934 East 55th Place

Tulsa, OK 74146

Style 711: Bolted Restraining Couplings

Ordinary mechanical couplings provide only a seal on the pipe end when installed. They do not prevent the pipe from pulling out of the coupling.

The Style 711 provides both a seal and a restraint

- As the coupling bolts are tightened, the coupling followers compress the gaskets and then force the steel grip rings to collapse around the pipe end, providing a restraint

- This gripping action increases as the pipes attempt to come out of the coupling

Meets or exceeds the requirements of D.O.T. Code 192.283(b) provided the proper Dresser reinforcing insert stiffener is used in the P.E. pipe ends.

Conductive vs. Insulating Coupling Design

- Conductive: used on lines that are to be electrically joined so as to share cathodic protection

- Insulating: used on lines that are to be electrically isolated (or sectionalized) for cathodic protection, or for insulating between pipe and dissimilar metals

Style 90: Universal Products

The “universal” Style 90 locking design creates a positive pipe restraint. As the nut is tightened, it compresses the gasket, which forces the steel lock rings to collapse around the pipe. The gripping action increases as the pipe attempts to move out of the coupling.

Available in insulated restraining couplings

- Features a restraining end and an insulated restraining end

Style 39: Coupling

The Dresser coupling consists of one cylindrical middle ring, 2 follower rings, 2 resilient gaskets and a set of steel track-head bolts. The middle ring has a conical flare at each end to receive the wedge portion of the gaskets. The follower rings confine the outer ends of the gaskets. Tightening bolts draw the follower rings toward each other, compressing the gaskets in the spaces formed by the follower rings, middle ring flares, and pipe surface providing a flexible, leak-proof seal

Style 39 Couplings are widely used on lines which are to be electrically isolated for cathodic protection, or for insulating between pipe of dissimilar metals. One pipe end is completely insulated from the coupling and opposite pipe end, while the armored gasket on the other end bonds the coupling to the pipe where it can share cathodic protection currents. Can be supplied with insulating features on both ends if required.

Style 110: Reinforcing Sleeve

Split reinforcing sleeve for repair of welded joints

Ready for field welding without preheating, using ordinary field welding procedures. All sleeves are factory prepared with standard welding bevel, machine flame cut for uniformity and ease of welding, and come with a drilled vent hole to preclude pressure build-up between sleeve and pipe

Minimum yield strength 50,000 psi, ultimate strength 70,000 psi.

Style 220: Reinforcing Sleeve

Similar to the style 110, the 220 encompasses a “pumpkin” sleeve design and are commonly used to repair corrosion pits and stress cracks and offer permanent repair over leaking couplings, flanges, valves, or screw collars

Minimum yield strength 50,000 psi, ultimate strength 70,000 psi

Blackhawk: Hot Tap & Line Stop Fittings

Pressure control fittings for threaded 1-1/4”–3” and flange fittings from 4”-12”

LS-2 fittings are designed, tested and manufactured to meet and exceed the code area replacement requirements for pressure containment per ASME/ANSI B31.8

Split sleeve fitting are also manufactured with side outlet, spherical configurations and with a weld neck flange for hot tapping

When field welding is not an option, Dresser offers the Style 50 mechanical sleeve integrated with Style LS-2 fittings with side outlets for hot tap service connections

YS12-CI

Y Strainer, Cast Iron, ANSI Class 250, Threaded Ends, Epoxy Painted, Gasketed Caps, Plugged Blow-off

YS61-CI

Y Strainer, Carbon Steel, ANSI Class 150, Flanged Ends, Bolted Cover, Epoxy Painted, Plugged Blow-off

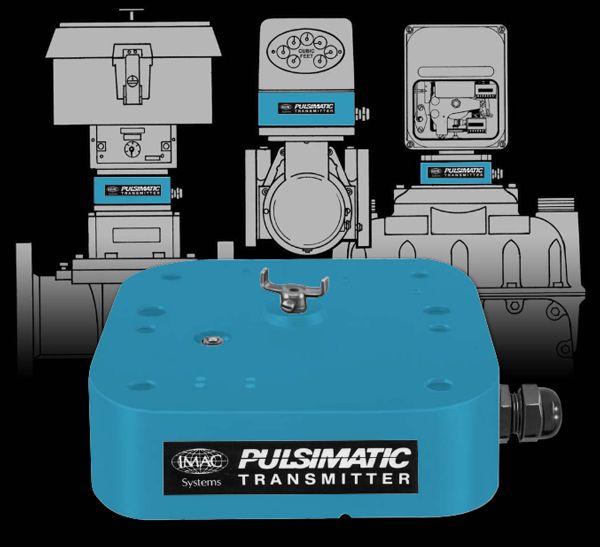

Pulsimatic Transmitter

THE IMAC PULSIMATIC TRANSMITTER is the economical way to transmit uncorrected volume output data from gas meters to remote totalizing and recording equipment. Available in ten different pulse outputs to fill most requirements, the PULSIMATIC TRANSMITTER has a virtually indestructible low profile that does not interfere with existing piping arrangement.

- Operates at extremely low torque

- One-piece, precision machined cast aluminum housing provides the protection for the pulsing mechanism along with precise mechanical action

- Single or double independent outputs available on all models FITS all types of industrial size meters with a vertical mechanical index: Diaphragm, Rotary, Turbine

- Extremely FAST and EASY field mounting, mounts between meter and index or instrument

- Ideal for data acquisition systems, AMR (automated meter reading), AMI (advance metering infrastructure), remote totalization, PLC, and SCADA systems

The IMAC Pulsimatic Transmitter fits all types of industrial/commercial size gas meters with vertical mechanical index (Diaphragm / Turbine / Rotary). The Pulsimatic Transmitter also acts as a secondary source of count if the meter index fails. For residential/domestic meters please see our Domestic Meter Pulser.

Many different options are available; please consult the literature for more information.

Pete's Plug® temperature and pressure test plug

- The Pete’s Plug® allows pressure and temperature readings to be taken without leaving costly gauges on the line

- The Pete’s Plug® has two self-closing valves improve the speed of valve closure

- Available in various thread sizes, lengths, and materials suitable for all applications

- Eliminates extra fittings for insulated applications

Pete's Plug II® allows you to take pressure or temperature readings quickly and eliminates the need for leaving costly gauges or temperature indicators on the line. Depending on the applications, the Pete's Plug can be operated to a maximum of 500 PSIG and 200°F or 275°F for neoprene or nordel respectively. Maximum working pressures of 1000 PSIG can be attained with neoprene or nordel at temperatures from 140°F to -20°F.

This enhanced version of Pete's Plug® is still the only pressure and temperature test plug with two self-closing valves, but the valves are improved with interaction which speeds valve closure. Pete's Plug II® is available in various pipe thread sizes, lengths, and materials to satisfy each application. The XL series Pete's Plug II® will allow you to insulate the test point and not completely cover the Pete's Plug II®. The XL Pete's Plug II® eliminates extra fittings for insulated applications.

Do not be fooled by imitation Pete’s Plugs® with single cores, look for the embossing right on the plug body that says "Pete’s Plug II"®

The Pete’s Plug is a registered trademark and valve design is fully patented.